While most photovoltaic (PV) module IV curve and peak power testers on the market share similar voltage, current, and power measurement ranges and accuracy specifications, their actual performance and quality vary significantly. How can you choose the right testing equipment?

1. Selecting the Appropriate Measurement Range

Modern large-scale centralized PV plants widely adopt 1500V voltage-level technology, and high-power PV modules increasingly feature short-circuit currents exceeding 15A.

Recommended Models:

GMC-I PROFTEST PV1500: 1500V, 20A DC measurement range

GMC-I PROFTEST PV1540: 1500V, 40A DC measurement range

GMC-I PV1525-IV: 1500V, 25A DC measurement range

2. High-Level Safety Assurance

PV strings can reach 1500V DC open-circuit voltage, posing risks such as arcing during connector insertion/removal or short circuits, which may cause injuries or equipment damage.

Safety Solution:

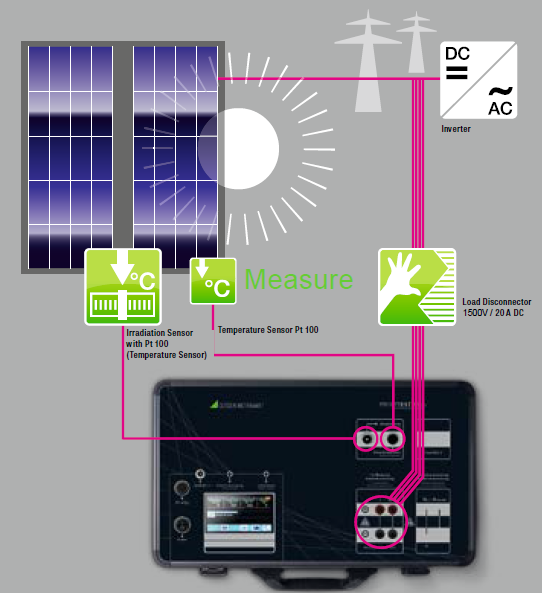

GMC-I PROFTEST PV1500 & PV1540: Include a 1500V/20A DC short-circuit protector to effectively mitigate these risks.

3. Instantaneous Irradiance Fluctuation Monitoring

During field testing, solar irradiance can fluctuate by hundreds of W/m² within milliseconds, affecting measurement accuracy.

Solution:

GMC-I PROFTEST PV1500 & PV1540: Provide real-time irradiance measurement with millisecond-level fluctuation detection for reliable data.

4. Ultra-Fast Testing Speed

Changes in environmental conditions (e.g., irradiance) during testing can impact accuracy.

Advantage:

GMC-I PROFTEST PV1500 & PV1540: Complete measurements in as little as 20ms, minimizing irradiance-induced errors—far faster than competing devices.

5. Ensuring Field Measurement Accuracy

Peak power is defined under Standard Test Conditions (STC), traditionally requiring complex lab measurements. While many testers perform well in controlled environments, their field accuracy, stability, and repeatability are often poor.

Breakthrough Technology:

GMC-I PROFTEST PV1500: Uses an algorithm developed by Prof. Wagner (Dortmund University of Applied Sciences) to directly determine peak power, internal series resistance, and shunt resistance in the field—without needing manufacturer module specifications.

6. Peak Power Measurement Repeatability

Some brands claim high lab-calibrated accuracy but suffer from poor field repeatability, forcing technicians to retest repeatedly.

Key Consideration:

Since irradiance and temperature vary constantly, testers must convert field-measured peak power to STC values for meaningful comparison with rated parameters. Consistent STC results across different conditions are the true benchmark of a tester’s reliability.

GMC-I Advantage:

PROFTEST PV1500 & PV1540: Feature GB/T18210-2000-compliant supercapacitive loads to eliminate capacitance effects, ensuring high-precision measurements.

Peak power repeatability: ±2% (actual field consistency exceeds this—see real-world PV plant data).

7. Comprehensive Accessories for Complex Field Conditions

The testers come with a full suite of accessories to handle diverse on-site challenges.

This guide highlights critical selection criteria while emphasizing GMC-I’s technological leadership in safety, speed, accuracy, and field reliability. Let me know if you'd like any refinements!